These are 15 reasons why Lincoln Auto Lubrication Systems are a must on today's Machinery.

| 1 | Reduces Repairs: |

| 2 | Prevents Waste of Lubricant: by dispensing precise amounts. |

| 3 | Reduces Man Hours: by delimiting manual lubrication. |

| 4 | Eliminates Machine Downtime: thereby increasing production. |

| 5 | Eliminates Product Spoilage: by controlling amount of lubricant to bearing. |

| 6 | Reduces Energy Requirements: by increasing machine efficiency (lowers bearing friction). |

| 7 | Increases Machine Output: by allowing faster speed in operation of machine. |

| 8 | Safety: no climbing on or over machinery, also safe lubrication of bearings inaccessible due to gas, fumes or height. |

| 9 | Machine Tolerances: are maintained longer by consistent automatic lubrication. |

| 10 | Better Housekeeping: a closed, sealed system eliminated spillage. Machines remain cleaner. No spillage and promotes safer environment for workers. |

| 11 | Promotes more Efficient Lubrication: lubricates while machine is running and delivers the right lubricant in the right amount at the right time. |

| 12 | Reduces Rejects: by maintaining closer bearing tolerances which allow for closer product tolerances. |

| 13 | Eliminates Bearing Contamination: by supplying lubricant from a closed circuit. Most oilers do not clean grease before manually lubricating. |

| 14 | Purges Bearing: in intense dirty work environments. Automatic lubrication Systems will purge or flush bearings thus reducing bearing failures due to contamination. |

| 15 | Bottom Line: automatic lubrication reduces manufacturing costs thereby allowing companies to increase profits and remain competitive in the marketplace. |

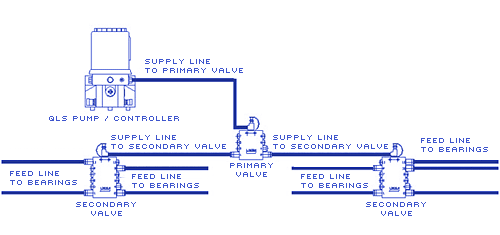

Automated lubrication applies smaller amounts of lubricant frequently, while the equipment is running, maintaining

the correct amount of grease in the bearing at all times. This is compared below to the feast and famine conditions

often associated with manual lubrication.

Why Bearing Fail? Manual Lubrication

Why Auto Lubrication is better? Automated Lubrication

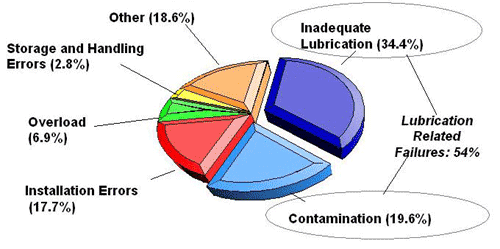

In a study conducted by a major component manufacturer,over 50% of failures are the result of improper lubrication.